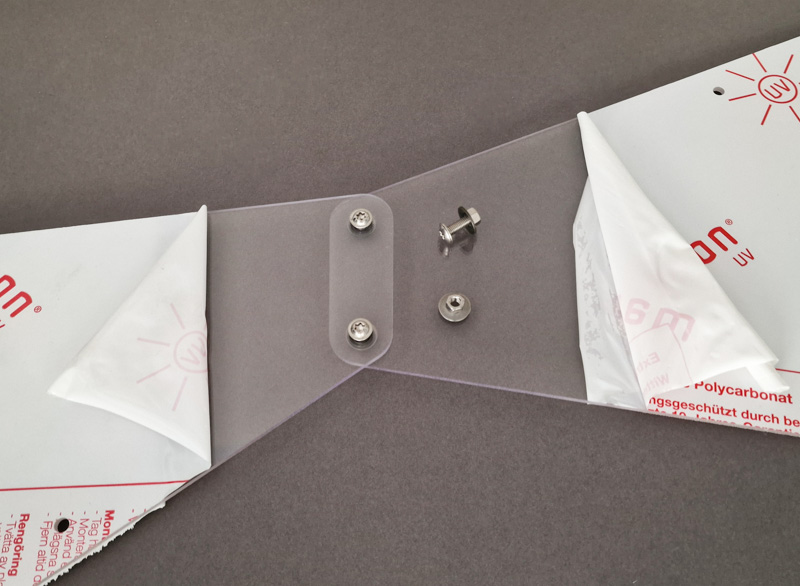

Screwing of the dome segments

The individual Makrolon segments of the dome are screwed together. In order to ensure that the bolted connections meet the requirements in terms of load distribution, connection rigidity and long-lasting corrosion protection, we only use bolts and nuts with high stainless steel grades from reputable manufacturers. For screw heads on the outside of the dome that are exposed to a wide range of weather conditions, we use stainless steel A4 grade crown screws, the surface of which remains rust and corrosion-free even in the most extreme weather conditions.

Screw sizes: M5 x 12 /A4/TX, M5 x16 /A4/TX (Torx)

Nuts: M5/A2/ nut with free-moving washer

The nuts used on the inside of the dome (protected from the weather) are A2 grade stainless steel to minimise the phenomenon of cold welding with the bolts. The nuts have a rotating washer that is fixed to the nut.

When assembling or disassembling the dome, these special nuts prevent the Makrolon®UV segments from being damaged. The rotating washer makes it impossible to dismantle the dome from the outside (burglary protection). When the screw and nut are fixed in place, they hide the identification number of the Makrolon®UV segments.

The screw heads are fitted with Torx screw inserts. Torx is a high-performance screw driver profile that ensures an optimal hold for the screwdriving tool even after assembling and disassembling the dome several times.